Kode QR

Babagan awake dhewe

Produk

Hubungi Kita

Telpon

Fax

+86-579-87223657

E-mail

alamat

Jalan Wangun, Street Ziyang, Wuyi County, Jinhua City, Provinsi Zhejiang, China

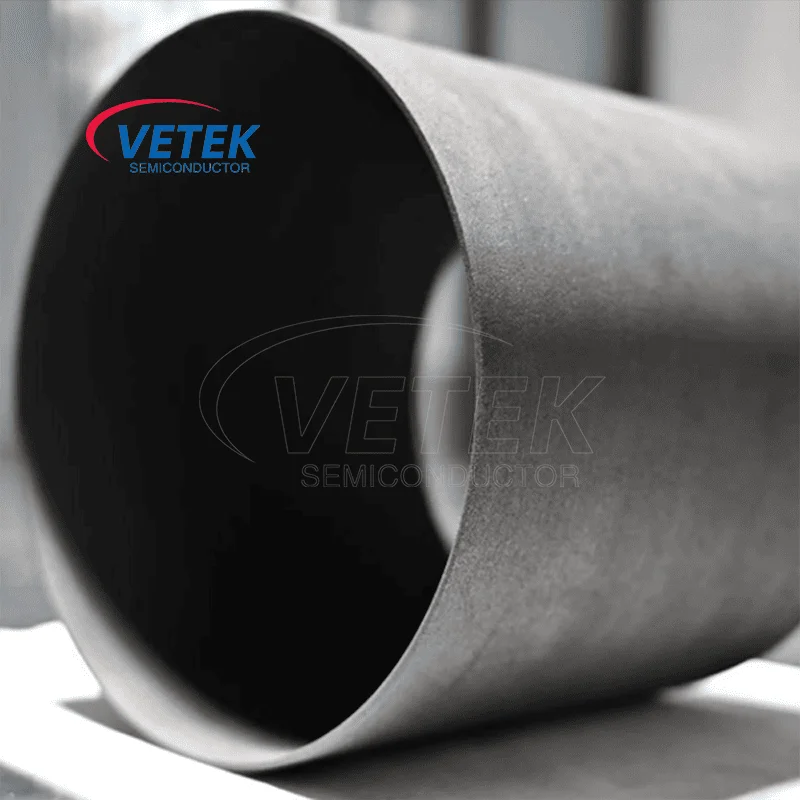

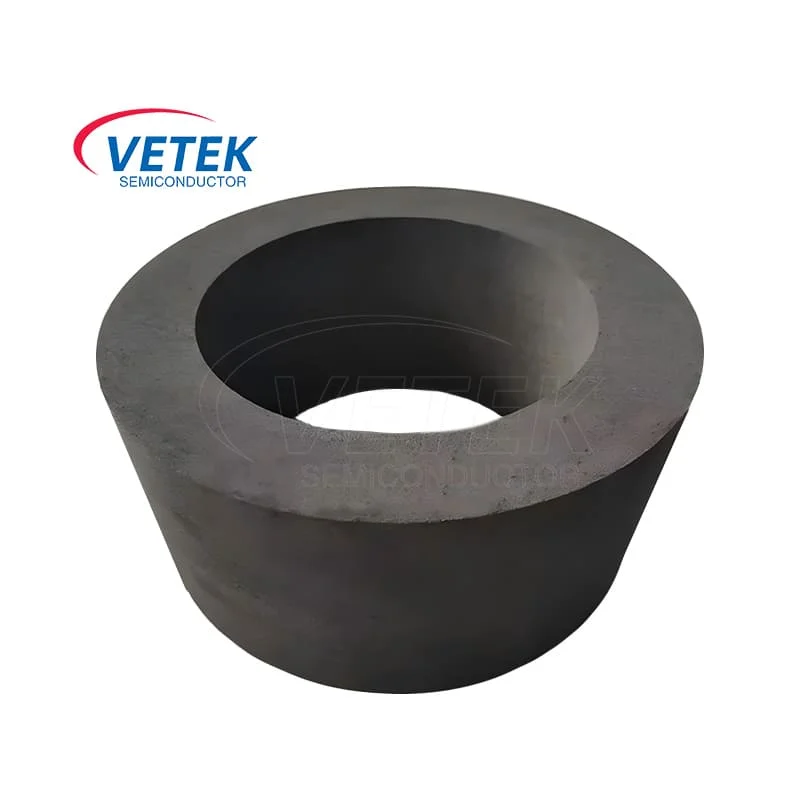

Produser produsen SIC biasane nggunakake desain sing bisa ditindakake kanthi silinder grafit kanggo proses lapangan sing panas. Desain iki nambah area penyuap lan volume biaya. Proses anyar wis dikembangake kanggo ngatasi cacat Crystal, stabilitas transfer massa, lan nambah kualitas kristal SIC. Iki kalebu cara fiksasi kristal tray tanpa wiji kanggo ekspansi termal lan relief stres. Nanging, sumber pasar winates saka grafit sing bisa dilalekake lan grafit keropos nyebabake tantangan kanggo kualitas lan ngasilake kristal tunggal sik.

1.Photan toleransi lingkungan suhu - produk bisa nahan lingkungan 2500 derajat Celsius, nuduhake resistensi panas sing apik banget.

2.stict kontrol porositas - semikonduktor vetek njaga kontrol porositas sing kenceng, njamin kinerja sing konsisten.

3.ultra-dhuwur kesucian - bahan grafit sing bisa digunakake entuk kemurnian tingkat sing dhuwur liwat proses pemurnian sing angel.

4. Kapabilitas Pariwisap Partikel Lumahing Partikel - Vetek Semikonduktor duwe kemampuan lan resistensi pemikat partikel lumahing sing apik kanggo adhesion bubuk.

5. Pengangkutan, panyebaran, lan keseragaman - Struktur keropos saka grafit nggampangake transportasi lan panyebaran gas sing efisien, ngasilake keseragaman gas lan partikel.

6.Sektian kontrol lan stabilitas - vetek semikonduktor negesake kesucian, isi sing ora pati rendah, lan stabilitas kimia kanggo njamin kualitas ing wutah kristal.

7.Temperatur kontrol lan keseragaman - konduktivitas termal saka grafit sing bisa ndadekake distribusi suhu seragam, nyuda stres lan cacat nalika tuwuh.

8.Satsa solute bedane lan tingkat pertumbuhan - Struktur keropos promosi sanajan distribusi solute, nambahake tingkat wutah lan keseragaman kristal.

Veteksemicon porous graphite materials are your ideal procurement choice for precision thermal processing and vacuum applications. With high porosity, uniform pore distribution, and excellent chemical resistance, Veteksemicon's porous graphite is engineered to meet the strict demands of advanced semiconductor manufacturing, filtration systems, and fuel cell components. These materials enable efficient gas diffusion, fluid flow control, and thermal management, making them indispensable in processes like vacuum chucks, electrochemical applications, and battery electrodes.

Each porous graphite block or plate is manufactured using advanced graphite molding and sintering techniques, ensuring optimal performance in high-temperature and corrosive environments. Due to its open-cell microstructure and customizable pore size, our porous graphite offers superior permeability and thermal conductivity while maintaining dimensional stability under extreme conditions.

This category also covers related entities such as graphite vacuum plates, porous graphite discs, frequently used in semiconductor wafer handling and energy systems.

Discover more product details on Veteksemicon's Porous Graphite product page or contact us for technical specifications and custom solutions.

+86-579-87223657

Jalan Wangun, Street Ziyang, Wuyi County, Jinhua City, Provinsi Zhejiang, China

Hak Cipta © 2024 Vetek Somiconductor Teknologi Co, Ltd kabeh hak dilindhungi undhang-undhang.

Links | Sitemap | RSS | XML | Privacy Policy |