Kode QR

Babagan awake dhewe

Produk

Hubungi Kita

Telpon

Fax

+86-579-87223657

E-mail

alamat

Jalan Wangun, Street Ziyang, Wuyi County, Jinhua City, Provinsi Zhejiang, China

Persiapan epitaries carbide berkualitas tinggi gumantung ing teknologi lan peralatan lan peralatan sing apik. Saiki, metode pertumbuhan epitails epitails sing paling akeh digunakake yaiku deposisi uap kimia (CVD). Nduwe kaluwihan kontrol trenyun film ketebalan epitise lan konsentrasi, tingkat pertumbuhan moderat, kontrol proses kanthi otomatis, lan liya-liyane, lan minangka teknologi sing bisa dipercaya kanthi komersial.

Silikon Carbide CVD Epitexy umume ngetrapake tembok panas utawa peralatan cvd tembok, sing njamin lampahing epitimo 4h kristal, ing antarane negara aliran udara sing dhuwur, bisa uga ana ing antarane tingkat aliran udara lan reaktor struktur vitor.

Ana telung pratondho utama kanggo kualitas tungku epitixial, sing pertama yaiku kinerja pertumbuhan ECitoxial, kalebu keseranan kerempat, kanthi nggunakake keseragaman, tingkat kekurangan; Sing nomer loro yaiku kinerja suhu saka peralatan kasebut dhewe, kalebu tingkat pemanasan / adhem, suhu maksimal, keseragaman suhu; Pungkasan, kinerja biaya peralatan kasebut dhewe, kalebu rega lan kapasitas unit siji.

CVD tembok panas cvd (model khas PE1O6 saka perusahaan LPE PE1O6 saka LPE Planet CVD (dituduhake dening model cvd tembok (sing khas - minangka model sing paling panas ing AIxtron G5ww) minangka solusi teknis epitraam sing wis diwujudake ing aplikasi komersial ing tahapan iki. Telung piranti teknis uga duwe ciri dhewe lan bisa dipilih miturut permintaan. Struktur kasebut dituduhake kaya ing ngisor iki:

Insulasi Downtream

Insulasi utama sisih ndhuwur

Halfmoon ndhuwur

Penebat hulu

Piece Transisi 2

Piece Transisi 1

Nozzle Air njaba

Torkel tapered

Nozzle gas Outer argon

Nozzzle gas Argon

WAFER Dhukungan piring

Pin Center

Pengawal Pusat

Tutup Perlindungan Downstream

Tutup perlindungan tengen mudhun

Tutup pangreksan kiwa

Tutup Perlindungan Tengen Upstream

Tembok sisih

Cincin grafit

Perlindungan sing dirasakake

Nyengkuyung krasa

Blok kontak

Silinder outlet gas

Disk Planetik SIC lapisan & disk planet planet

NUFLare (Jepang): Perusahaan iki nawakake tungku vertikal vertikal dual-ramab sing nambah kanggo ngasilake produksi. Peralatan kasebut duwe rotasi kanthi cepet nganti 1000 révolusi saben menit, sing regane migunani banget kanggo keseragam epitoxial. Kajaba iku, arah AirFlow beda karo peralatan liyane, kanthi vertikal mudhun, saéngga nyuda partikel partikel lan nyuda kemungkinan tetesan partikel mudhun ing wafer partikel. Kita nyedhiyakake komponen grafit sing ditutupi ing inti kanggo peralatan iki.

Minangka supplier komponen peralatan epitaksi SIC, Sikmikondduktor setya menehi pelanggan komponen kanthi kualitas tinggi kanggo ndhukung sukses epitexy SIC.

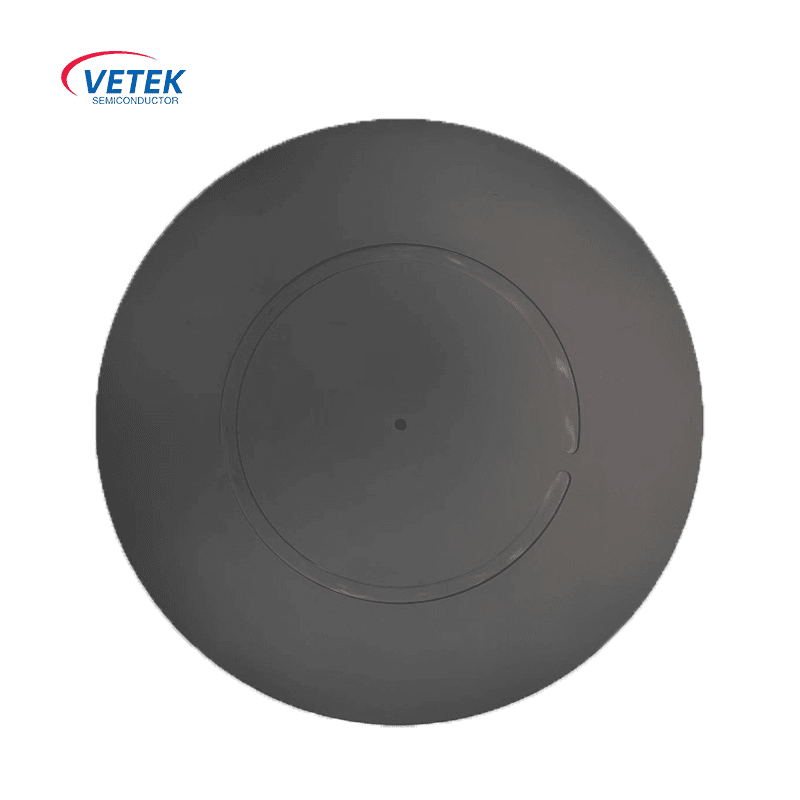

Veteksemicon silicon carbide epitaxy is your advanced procurement option for producing high-performance 4H-SiC and 6H-SiC epitaxial layers used in wide bandgap semiconductor devices. SiC epitaxy enables the formation of defect-controlled, dopant-engineered epitaxial layers critical for high-power, high-frequency, and high-temperature electronic devices.

Our offering includes specialized components such as SiC epitaxial susceptors, SiC-coated wafer holders, and epitaxy process rings, tailored for use in horizontal and vertical MOCVD and CVD reactors, including platforms by Veeco, Aixtron, and LPE. Veteksemicon’s parts are coated with high-purity CVD SiC, ensuring chemical compatibility, temperature uniformity, and minimal contamination during epitaxial layer growth.

Silicon carbide epitaxy is essential for fabricating power MOSFETs, IGBTs, and RF components, particularly in automotive, energy, and aerospace applications. The epitaxial process requires extremely precise control over doping concentration, layer thickness, and crystallographic orientation, which is why substrate compatibility and thermal stability of reactor parts are critical.

Relevant terms in this category include 4H-SiC epitaxial wafer, low-defect-density epitaxy, SiC epi-ready substrates, and wide bandgap semiconductors. Veteksemicon supports both research-scale and volume production needs with stable, repeatable, and thermally robust component solutions.

To learn more about our silicon carbide epitaxy support materials, visit the Veteksemicon product detail page or contact us for detailed specifications and engineering support.

+86-579-87223657

Jalan Wangun, Street Ziyang, Wuyi County, Jinhua City, Provinsi Zhejiang, China

Hak Cipta © 2024 Vetek Somiconductor Teknologi Co, Ltd kabeh hak dilindhungi undhang-undhang.

Links | Sitemap | RSS | XML | Privacy Policy |