Kode QR

Babagan awake dhewe

Produk

Hubungi Kita

Telpon

Fax

+86-579-87223657

E-mail

alamat

Jalan Wangun, Street Ziyang, Wuyi County, Jinhua City, Provinsi Zhejiang, China

Vetek Semiconduktor minangka pabrikan utama keramik SIC Keramik kanggo industri semikonduktor. Liwati iso9001, vetek semikonduktor duwe kontrol sing apik kanggo kualitas. Vetek Semiconduktor mesthi setya dadi inovator lan pimpinan ing industri keramik SIC keramik.

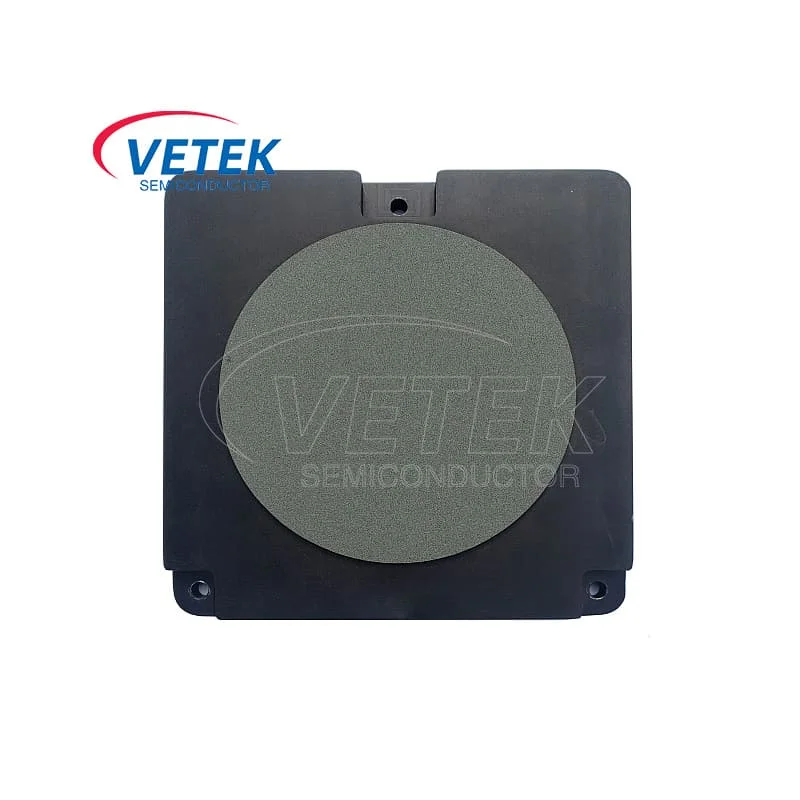

Disk keramik SIC

Keramik SIC Pokus yaiku materi keramik sing dipecat ing suhu sing dhuwur lan duwe akeh interconnected utawa ditutup. Iki uga dikenal minangka Piala Sukses Vacuum Vacuus, kanthi ukuran pore wiwit saka 2 nganti 100um.

Keramik SIC Keropis wis digunakake ing metalurgi, industri kimia, perlindungan lingkungan, biologi, semikonduktor lan lapangan liyane. Keramik SIC Keropos bisa disiapake kanthi cara foaming, metode Sol Gel, cara casting tape, cara sintering padhet lan metode pyrolysis impregnation.

Preparation Keramik Sik Porous dening Cara Sintering

Properties Keramik Carbide Porous disiapake kanthi cara sing beda minangka fungsi porositas

![]()

Pupung keramen keramik SICCOCT SIC ing pabrik wafer Semikonduktor

Keramik SIC Vetek Semikonduktor duwe peran clamping lan nggawa wafers ing produksi semikonduktor. Dheweke padhet lan seragam, dhuwur kanthi kekuwatan, apik ing udhara, lan seragam ing adsorption.

Kanthi efektif ngatasi akeh masalah sing angel kayata indhuksi wafer lan risak elektraskat chip, lan mbantu entuk pangolahan wafers sing berkualitas tinggi.

Diagram kerja keramik sik keropos:

Prinsip kerja keramik SIC Keropis: wafer silikon tetep dianjurake pariwara adsorpsi vakum. Sajrone ngolah, bolongan cilik ing keramik SIC keropos digunakake kanggo njupuk udhara ing antarane silikon wafer lan permukaan keramik, saengga tuap silikon lan permukaan keramik ana ing tekanan, saéngga ndandani wafer silikon.

Sawise diproses, banyu plasma mili metu saka bolongan kanggo nyegah wafer silikon saka manut menyang permukaan keramik, lan ing wektu sing padha, wafer keramik dibersih.

Microsrapture saka keramik SIC keropos

Kaluwihan lan fitur:

● Rintangan suhu dhuwur

● Rintangan kanggo nyandhang

● Resistensi kimia

● Kekuwatan mekanik tinggi

● Gampang regenerasi

● Tahan kejutan termal sing apik banget

Item

unit

Keramik Sik Porous

Diameteripun pori

siji

10 ~ 30

Kapadhetan

g / cm3

1.2 ~ 1.3

Lumahing roughness

siji

2.5 ~ 3

Nilai Penyerapan Udara

Kpa

-45

Kekuwatan fleksibal

MPA

30 Konstantasi dielektrik

1mhz

33 Konduktivitas termal

W / (m · k)

60 ~ 70

Ana sawetara syarat sing dhuwur kanggo keramik SIC Porous:

1. Iklan vakum vakum kuwat

2. Flatness penting banget, yen ora ana masalah sajrone operasi

3. Ora ana ubah lan ora ana impurities logam

Mula, nilai penyerapan udara saka keramik Sik Sik Sikmonduktor tekan -45kpa. Ing wektu sing padha, dheweke wis tempus ing 1200 ℃ kanggo 1,5 jam sadurunge metu saka pabrik kanggo mbusak reged lan di rangkep ing kantong vakum.

Keramik SIC Potong digunakake ing teknologi pangolahan wafer, transfer lan tautan liyane. Dheweke wis nggawe prestasi sing apik kanggo ikatan, dicelek, pemasangan, polishing lan tautan liyane.

Order precision-engineered Porous SiC ceramics from Veteksemicon—ideal for thermal uniformity and gas control in semiconductor systems.

Veteksemicon’s porous silicon carbide (SiC) components are engineered for high-temperature plasma processes and advanced gas flow control. Ideal for PECVD, ALD, vacuum chucks, and gas distribution plates (showerheads), these components offer excellent thermal conductivity, thermal shock resistance, and chemical stability.

Our porous SiC features a controlled pore structure for consistent gas permeability and uniform temperature distribution, reducing defect rates and enhancing yield. It is widely used in wafer handling platforms, temperature equalizing plates, and vacuum holding systems. The material ensures mechanical durability under corrosive and high-load thermal conditions.

Contact Veteksemicon today to request custom Porous SiC solutions or detailed engineering parameters.

+86-579-87223657

Jalan Wangun, Street Ziyang, Wuyi County, Jinhua City, Provinsi Zhejiang, China

Hak Cipta © 2024 Vetek Somiconductor Teknologi Co, Ltd kabeh hak dilindhungi undhang-undhang.

Links | Sitemap | RSS | XML | Privacy Policy |