Kode QR

Babagan awake dhewe

Produk

Hubungi Kita

Telpon

Fax

+86-579-87223657

E-mail

alamat

Jalan Wangun, Street Ziyang, Wuyi County, Jinhua City, Provinsi Zhejiang, China

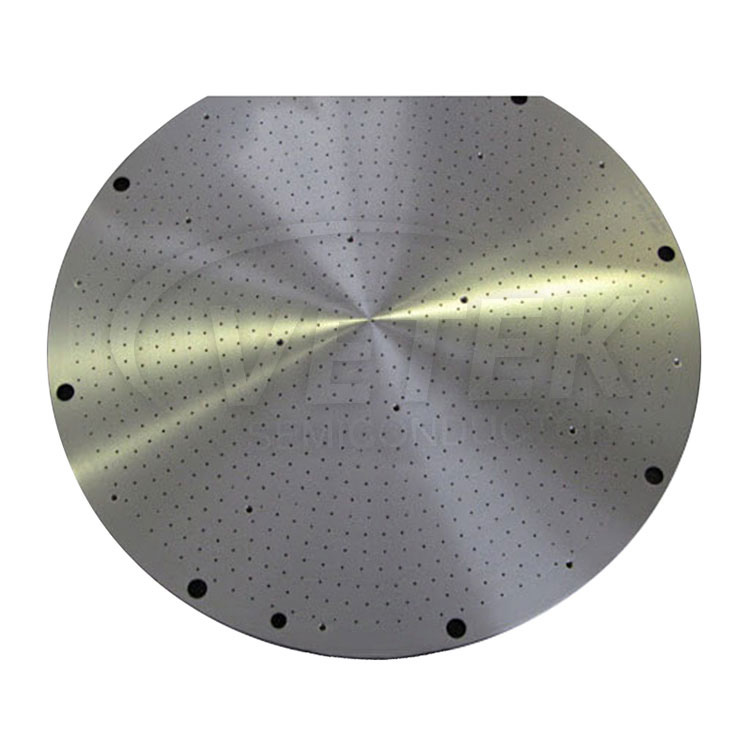

Vetek semikonduktor solicon karbida yaiku komponen keramik penting ing peralatan plasma etching, karbida soliconCvd silikon karbida) bagean ing peralatan etching kalebuFokus Rings, Gas Showerheas, dering, cincin pinggir, lsp. Amarga réaktivitas silikon karbida lan cvd silikon) menyang klorin - lan bahan sing cocog karo cvd, minangka bahan sing cocog karo cvd, minangka bahan sing cocog kanggo peralatan sing cocog karo cemara lan komponen liyane.

Contone, cincin fokus minangka bagean penting sing diselehake ing njaba wafer lan langsung kontak karo wafer, kanthi ngetrapake voltase menyang cincin kasebut, kanthi fokus ing plasma kanggo nambah keseragaman kanggo ngolah pangolahan. Dering fokus tradisional digawe saka silikon utawaKuarsa, Silikon konduktivitas minangka bahan cincin fokus sing umum, meh cedhak karo tumindak wafers silikon, nanging kekurangan tahan serangga fluorine, bakal ana efisiensi produksi serius.

SOliid Fokus FokusPrinsip kerja:

Perbandingan ring basis Adhedhasar lan cvd fokus CRD:

| Perbandingan karo Dering fokus ing Adhedhasar lan CVD Fokus Cincin | ||

| Item | Lan | CVD SIC |

| Kapadhetan (g / cm3) | 2.33 | 3.21 |

| Band Gap (EV) | 1.12 | 2.3 |

| Konduktivitas termal (w / cm ℃) | 1.5 | 5 |

| Cte (x10-6/ ℃) | 2.6 | 4 |

| Modulus elastis (GPA) | 150 | 440 |

| Hardness (GPA) | 11.4 | 24.5 |

| Rintangan kanggo nyandhang lan korosi | Miskin | Banget |

Vetek Somiconduktor nawakake karbida solor canggih canggih (CVD karbohicon karbida) kaya SIC Fokus dering SIC kanggo peralatan semikonduktor. Silikon solid kita fokus ing cincin tradisional Outperform ing babagan kekuatan mekanik, resistensi kimia, kekurangan suhu, lan tahan ulang Etate-iron.

Kapadhetan sing dhuwur kanggo tarif etching suda.

Penebat banget karo bandgap dhuwur.

Konduktivitas termal lan koefisien kurang ekspansi termal.

Rintangan lan kelainan mekanik sing unggul.

Hardness, nyandhang resistensi, lan resistensi karat.

Diprodhuksi nggunakakePLASMA-Meningkat Dipendheksi kimia (PECVD)Teknik, cincin fokus sik kita ketemu panjaluk proses etching ing pabrik semikonduktor. Dheweke dirancang kanggo nahan daya lan tenaga plasma sing luwih dhuwur, khusus ingPlasma sing bisa digayuh (CCP)Lanstem.

Cincin fokus vetek semikonduktor menehi kinerja lan linuwih sing luar biasa ing manufaktur piranti semikonduktor. Pilih komponen SIC kanggo kualitas lan efisiensi.

Veteksemicon solid silicon carbide is the ideal procurement material for high-temperature, high-strength, and corrosion-resistant components used in semiconductor and industrial applications. As a fully dense, monolithic ceramic, solid silicon carbide (SiC) offers unmatched mechanical rigidity, extreme thermal conductivity, and exceptional chemical durability in harsh processing environments. Veteksemicon’s solid SiC is specifically developed for critical structural applications such as SiC wafer carriers, cantilever paddles, susceptors, and showerheads in semiconductor equipment.

Manufactured through pressureless sintering or reaction bonding, our solid silicon carbide parts exhibit excellent wear resistance and thermal shock performance, even at temperatures above 1600°C. These properties make solid SiC the preferred material for CVD/PECVD systems, diffusion furnaces, and oxidation furnaces, where long-term thermal stability and purity are essential.

Veteksemicon also offers custom-machined SiC parts, enabling tight dimensional tolerances, high surface quality, and application-specific geometries. Additionally, solid SiC is non-reactive in both oxidizing and reducing atmospheres, enhancing its suitability for plasma, vacuum, and corrosive gas environments.

To explore our full range of solid silicon carbide components and discuss your project specifications, please visit the Veteksemicon product detail page or contact us for technical support and quotations.

+86-579-87223657

Jalan Wangun, Street Ziyang, Wuyi County, Jinhua City, Provinsi Zhejiang, China

Hak Cipta © 2024 Vetek Somiconductor Teknologi Co, Ltd kabeh hak dilindhungi undhang-undhang.

Links | Sitemap | RSS | XML | Privacy Policy |